Waste Management Chemical Storage Case Study

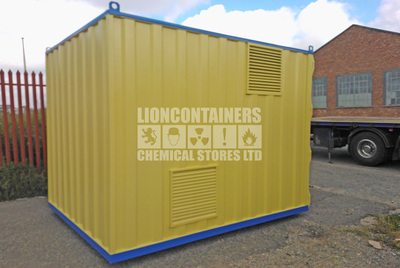

Lion Containers (Chemical Stores) Ltd received a quotation request from a large construction waste management company, they were looking for additional chemical storage and wanted to discuss this further with us. After some lengthy discussions regarding their specification, and after studying the drawings we supplied, the customer placed an order for a 10ft chemical storage container.

A small high quality unit was imperative for our customer, and as a result we built a structure to suit. From the ground up the unit was custom made, along with all the relevant apertures cut precisely as per the drawings and sketches agreed between the customer and ourselves. The interior floor of the unit was not that of a standard container, instead the floor was made up of a durbar sheet steel on either side of the unit with a strip in the centre for a grated bund and sump. Bays of shelving were supplied with the container which were fitted over the durbar sheet steel floors, this was to aid the customer with the unit's primary use of storage.

A two part company colour was applied, to ensure that the unit matched the surrounding areas and buildings of the customer's site. We ensured that the colours were an exact colour match, this was through collaboration with the customer. Finally, to top off the build, a high security hardened steel lockbox was fitted to the unit's double doors in order to add an additional security measure to the unit, when in situ.

All in all the conversion was a success and our customer was thoroughly pleased with the result. Our unit even found its way into a company-wide bulletin, that enabled us to perform additional works with this customer in the future. The order for the unit was received on the 25/03/14 and delivered on 25/06/14.

A two part company colour was applied, to ensure that the unit matched the surrounding areas and buildings of the customer's site. We ensured that the colours were an exact colour match, this was through collaboration with the customer. Finally, to top off the build, a high security hardened steel lockbox was fitted to the unit's double doors in order to add an additional security measure to the unit, when in situ.

All in all the conversion was a success and our customer was thoroughly pleased with the result. Our unit even found its way into a company-wide bulletin, that enabled us to perform additional works with this customer in the future. The order for the unit was received on the 25/03/14 and delivered on 25/06/14.

Fill out my online form.